Environmentally Friendly Sandblasting Room

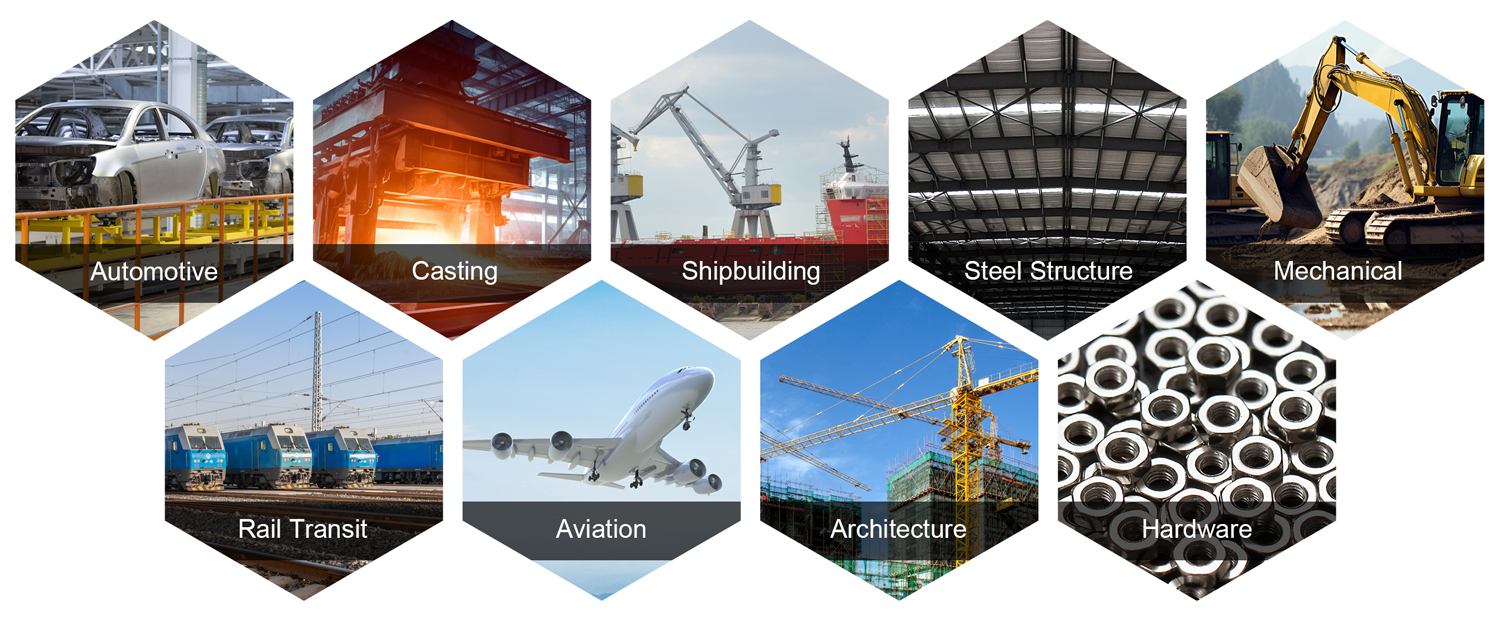

Used in manufacturing, automotive, aviation, construction and other industries.

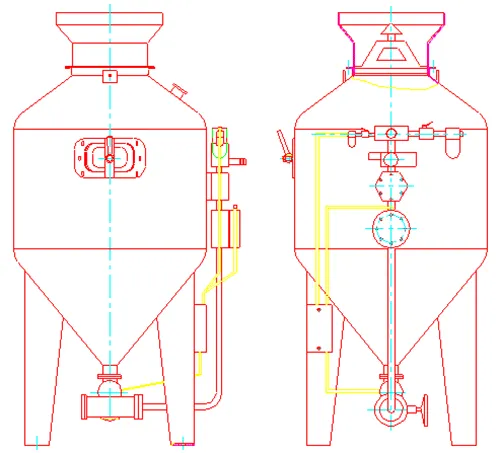

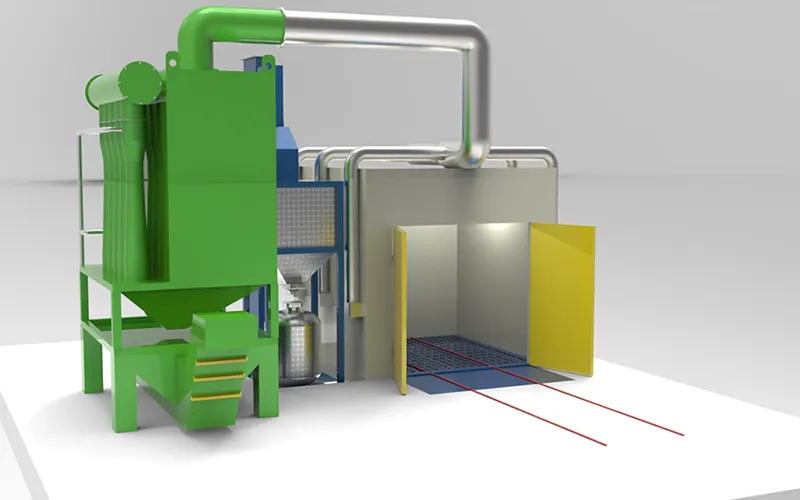

Sandblasting chamber body

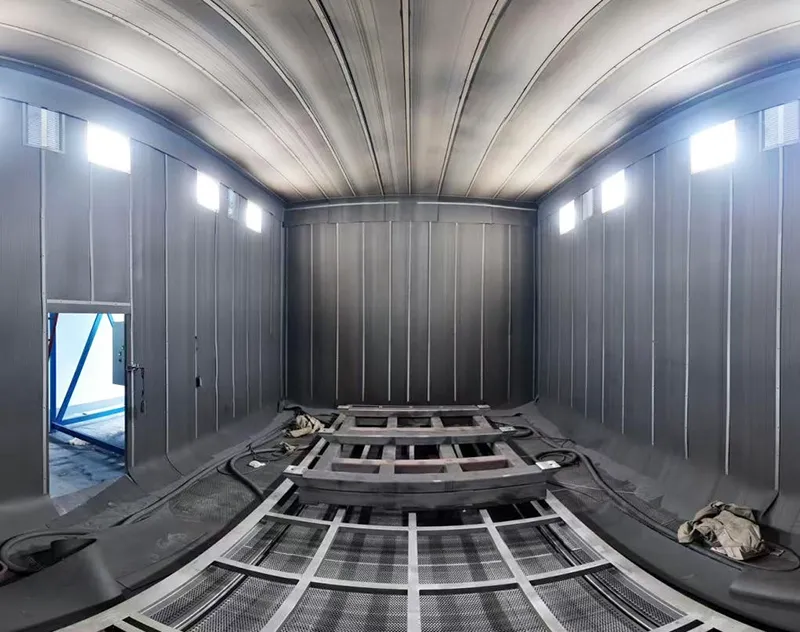

The sandblasting room is a workplace for sandblasting operations. The sandblasting room adopts 100mm square tube as the basic frame, 25 × 40 square tube as the internal support, and color steel plate sandwich panel as the outer layer. 5mm wear-resistant rubber plate is pasted inside, with beautiful appearance, easy installation, and anti-corrosion durability; The sandwich layer of color steel plate is made of PVC material

Sandblasting tank and protective mask

Equipped with a sandblasting tank. Temperature regulating protective mask. The temperature regulating protective mask consists of an air filter, a temperature regulator, a double-layer helmet, and protective clothing. Compressed air (with an air filtration accuracy of 0.5um) that has been cleaned of water vapor, oil and gas, rust, other dust particles, and unpleasant odors through an air filter slowly enters the double-layer helmet through a temperature regulator (with a temperature adjustment range of 10-45 ℃), providing operators with fresh and comfortable air at a moderate temperature. Coupled with the wide field of view of the mask, it greatly improves the working environment for workers during shot blasting and protects their physical health.

Bucket elevator

The bucket elevator consists of a cycloidal pinwheel reducer, upper and lower rollers, conveyor belt (or chain), hopper, closed material cylinder, and tensioning device

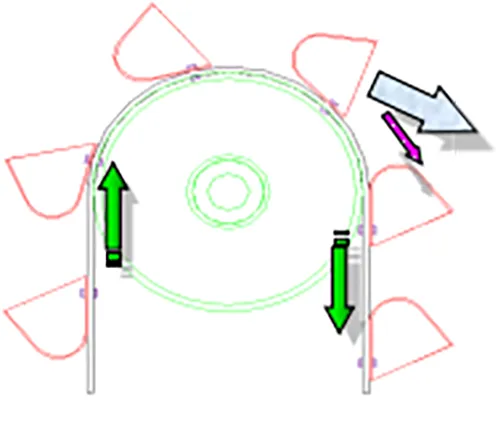

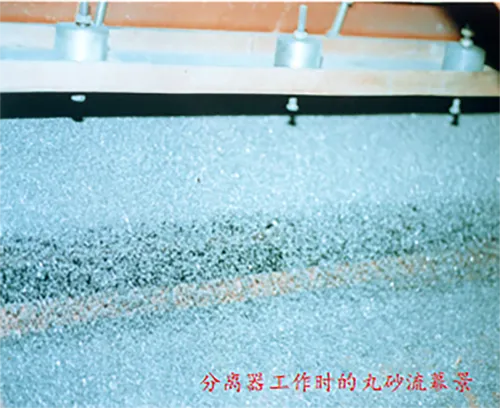

Separator

This machine adopts the BE type full curtain separator, which is produced by our company with the introduction of Swiss+GF+DAS and American Panbon technology. It consists of the following system components.

Sorting area, pellet silo, pellet control gate, etc.

Abrasive control system

Adopting our company's patented electric control bullet gate valve. It can automatically provide pellets to the shot blaster after a certain amount of time of shot peening accumulation.

Lighting system

The lighting system uses multiple metal halide lamps distributed around the room, and each lamp has a button to control its brightness, which can reach 2-3 times the standard brightness. The surface of each lamp is equipped with explosion-proof organic glass and wire mesh to strengthen the protection of the control lamp. The indoor illumination is greater than 250LUX.

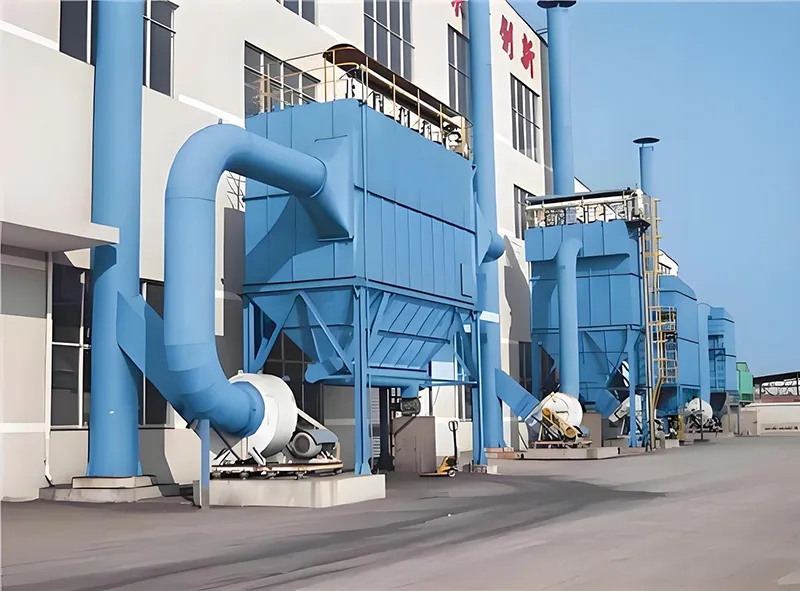

Dust removal system

The dust removal system includes filter cartridges, dust collectors, fans, and piping systems.

lectric control system

This system is mainly composed of high-quality low-voltage electrical components.

-This shot blasting machine adopts conventional control.

-The bullet circulation system has a fault alarm function, and if any component of the system malfunctions, the components above it will automatically stop running, causing the bullet to get stuck and burn out the power unit.

-The maintenance doors and other important parts of the shot blasting room are equipped with safety interlock switch devices, which means that when these parts are opened, important components such as the shot blaster cannot work.

-The underground foundation pit of the shot blasting room is equipped with safety light power sockets for easy maintenance and lighting.

-The dust collector has an automatic control blowback function

Sandblasting Room, also known as sandblasting room or sandblasting workshop, is a professional surface treatment equipment used for surface rust removal, descaling, oil removal or surface strengthening of large workpieces. Compared with the traditional open sandblasting method, the sandblasting room has significant advantages such as environmental protection, high efficiency, controllability and safety. It is particularly suitable for industries with strict surface treatment requirements such as shipbuilding, steel structure, wind power equipment, petrochemical, rail transportation, and automobile manufacturing.

◆ Product Features

Environmentally friendly and closed operation

The sandblasting room is a fully enclosed structure, with a powerful dust removal system, dust does not leak out, effectively improves the working environment, and meets environmental protection standards.

Suitable for large workpieces

The size of the room can be customized according to the size of the workpiece, supporting the sandblasting of long, large and heavy workpieces such as hulls, bridge steel beams, and large steel components.

Abrasive recycling

The efficient recovery and separation system can reuse the abrasive after sandblasting, saving material costs and improving economic benefits.

Human-machine safety protection design

The room is equipped with safety switches, protective clothing, ventilation helmets and other operating protection equipment to ensure the personal safety of operators.

Flexible customization function

Can be equipped with rail transportation system, automatic sandblasting robot arm, rotary table, lifting platform and other equipment to meet different process requirements.

Support a variety of abrasives

Can be applied to a variety of abrasives such as steel sand, steel shot, corundum, glass beads, quartz sand, etc., to adapt to different workpiece materials and processing standards.

◆ Product Advantages

Efficient rust removal: can meet ISO 8501-1 Sa2.5~Sa3 rust removal standards;

Energy saving and consumption reduction: high abrasive recovery rate, low system energy consumption, long equipment life;

Intelligent control: PLC centralized control, support remote monitoring and operation;

Low noise design: structural sound insulation treatment, reduce operating noise, improve the operating environment;

Easy maintenance: modular design of each system, easy to maintain, replace and upgrade.

◆ Application Industry

◆ FAQ

What workpieces are suitable for sandblasting rooms?

Sandblasting rooms are suitable for workpieces that are large, heavy, difficult to move or require high-quality surface treatment, such as hull steel plates, bridge components, wind turbine towers, pressure vessels, large steel structures, etc., and are particularly suitable for rust removal or roughening before spraying.

How does the sandblasting room achieve environmentally friendly operations?

The sandblasting room adopts a closed structure design and is equipped with a high-efficiency pulse dust collector, which can effectively capture the dust generated during the sandblasting process to prevent leakage and air pollution. At the same time, it is equipped with an abrasive recycling system to reduce material waste and meet environmental protection requirements.

Can the abrasive in the sandblasting room be reused?

Yes. The sandblasting room is equipped with an automatic recovery and separation system. The abrasives that have been sprayed are collected and collected through the ground conveyor belt. They enter the separator to remove dust and impurities and are reused, which greatly reduces the cost of consumables and improves operating efficiency.

◆ Company Introduction

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is the leading enterprise of the shot blasting machine industrial cluster in Dafeng District and has the title of "China Xituan Shot Blasting Machine Industrial Base".

Founded in May 2003, the company is a professional manufacturer of shot blasting equipment and accessories integrating R&D, design, manufacturing and sales. The company is located in Longfa Industrial Park, Xituan Town, Dafeng District. The registered capital is RMB 60 million, with 180 employees, including 40 scientific and technological personnel. The company currently covers an area of about 120 acres and a current construction area of 80,000 square meters.

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is located on the beautiful coast of the Yellow Sea, close to the Ningjingyan Expressway, Xinchang Railway and Tongyu River Golden Waterway, and close to Yancheng Airport for convenient transportation and communication. It has built a new plant and a supporting service system for technical and process collaboration, and has a complete set of gold processing equipment and dynamic balancing instruments and other testing methods.

The company always adheres to the quality tenet of "honesty and dedication, serving customers with sincerity", and the quality commitment of "meticulous manufacturing, ensuring satisfaction of each casting machine", and is determined to repay the society with quality, constantly carry out technological innovation, establish the good reputation of the "Longfa" brand, and do its best for the development of my country's casting machinery industry. All colleagues in the company warmly welcome friends from all walks of life at home and abroad to come to guide, exchange and cooperate, and create brilliance together!