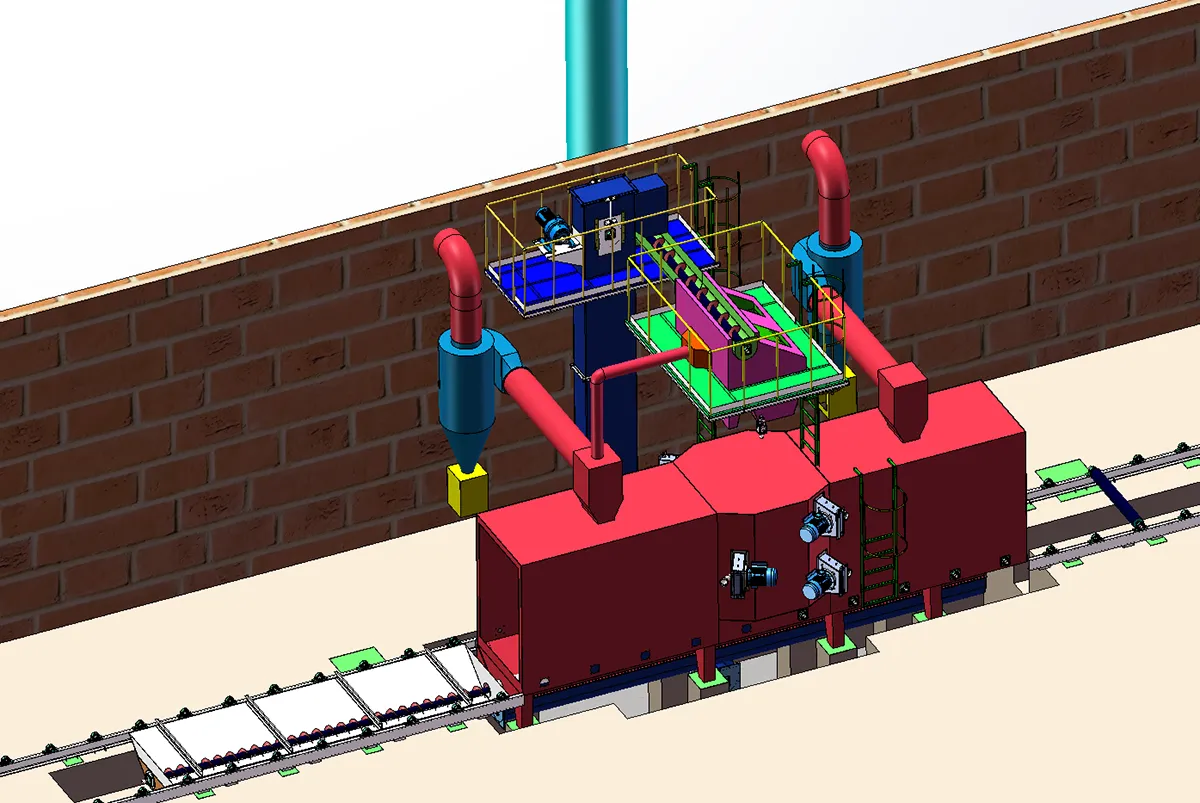

H-Beam Shot Blasting Machine

Applicable to various types of steel structural parts for buildings and engineering such as steel beams, steel columns, steel trusses, etc.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

◆ Product Configuration

| Model | QH69 Ultra | QH69 Max | QH69 Pro |

| Motor | Siemens | WEG | ZWT |

| Electronic control | Siemens | Mitsubishi | Chint |

| Plc | ✔ | ✔ | ✘ |

| Shot blasting chamber | Mn13 16mm | Mn13 12mm | High chromium cast iron 10mm |

| Blasting turbine accessories | Mold steel | Precision casting | High chromium cast iron |

| Warranty time | 3 Years | 2 Years | 1 Years |

◆ Product Parameters

| Type | QH(customizable) | |

| Workpiece Dimension |

Width and Height(mm) | 600-1300*600-2300 |

| Length(mm) | 3000-12000 | |

| Blasting wheel | Blasting Capacity(kg/min) | 4*200-10*200 |

| Power(kw) | 4*11-10-11 | |

| Roller table allows load (kg/m) | 500 | |

| Roller conveyor speed(m/min) | 0.4-4 | |

| Ventilation Capacity(m³/h) | 12000-24000 | |

| Steel shot circulation(T/h) | 50-150 | |

| Total Power (kw) | ≈70-200 | |

◆ Product Composition

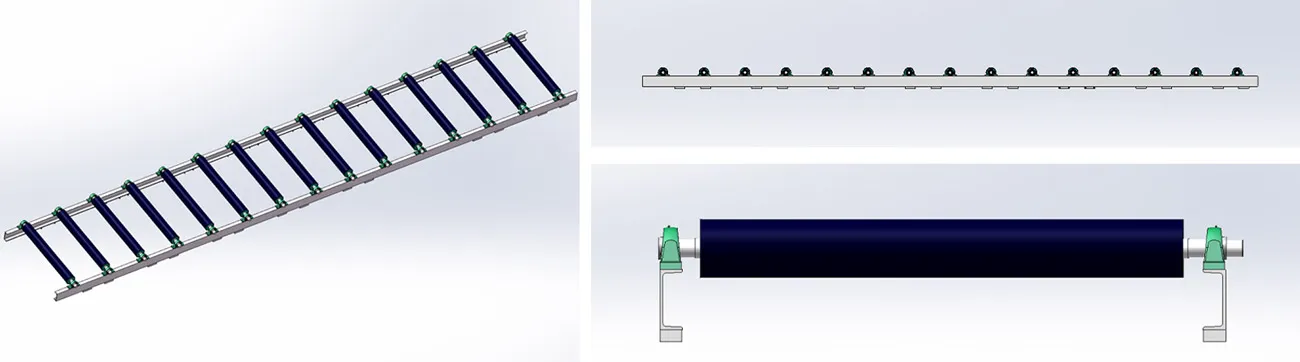

Roller Conveyor Systems

Composition: Feeding rollers, middle rollers, out-feeding rollers.

Loading capacity: 1000kg/m

Rollers Distance: 1 m.

Rollers Speed: 0.5-4 m per min.

Drive: Variable speed reducer.

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

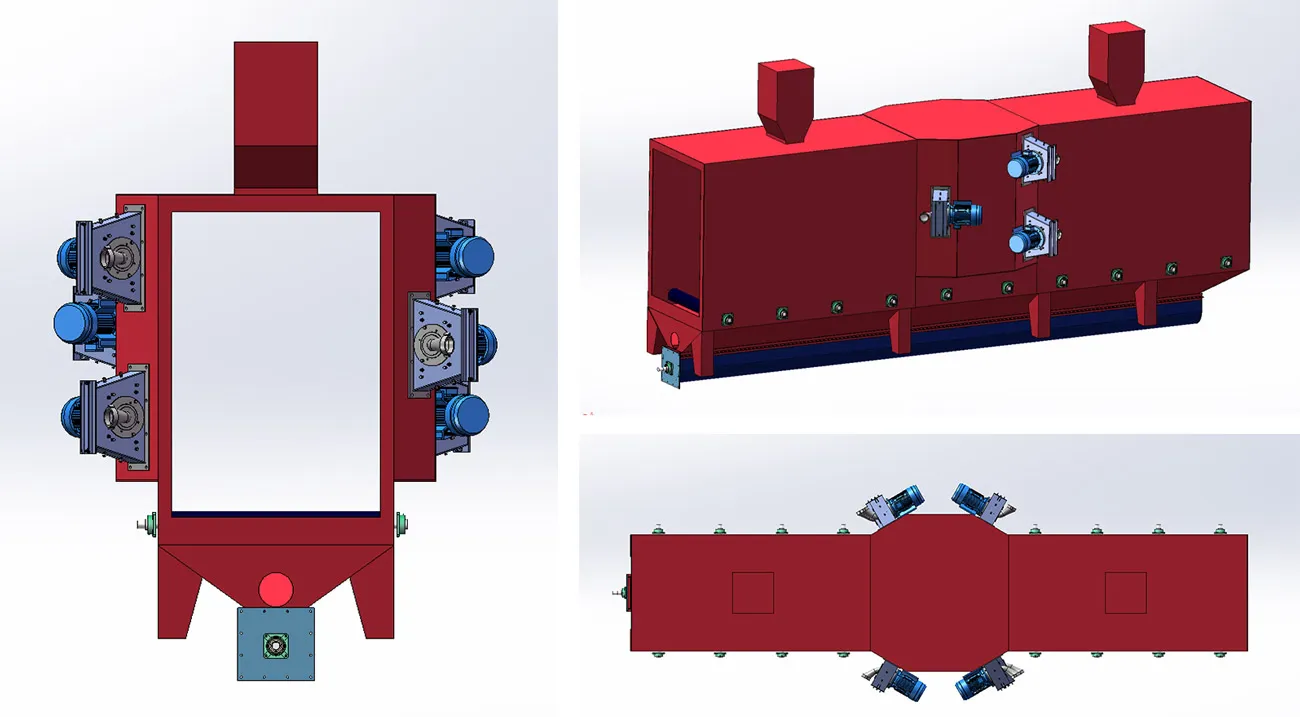

Blasting Chamber

Composition: Main blasting chamber, 2 auxiliary blasting chambers.

Auxiliary Blasting Chamber:Four layers rubber curtains

Main Blasting Chamber: Blasting wheels are mounted on chamber in different angles

Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit replacement.

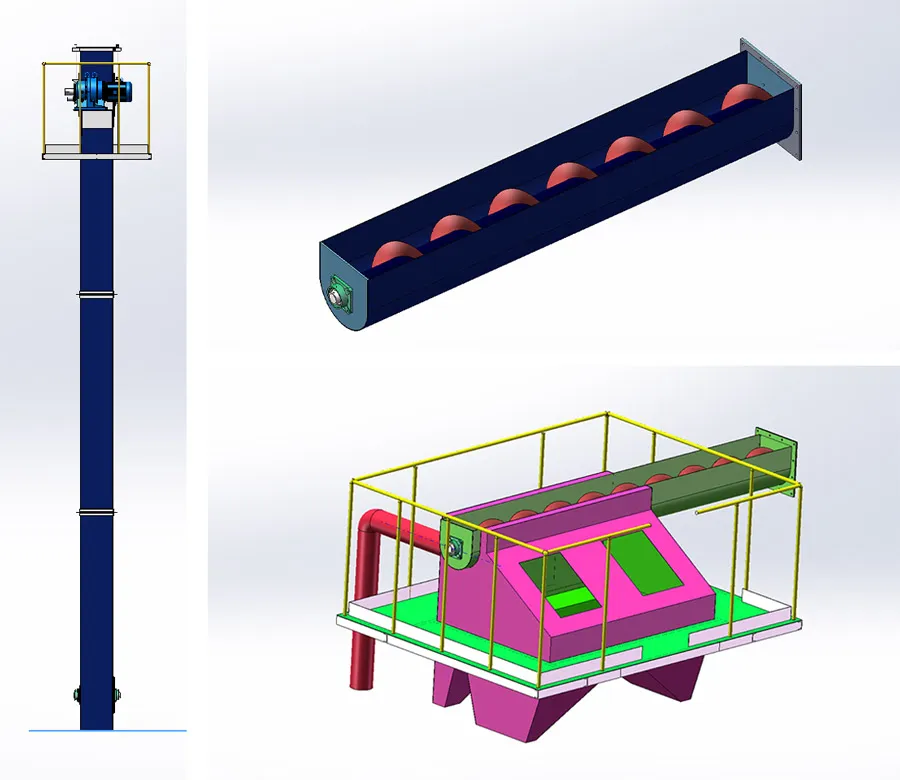

Abrasive Recycling System

Longitude Screw: collect abrasive at the bottom.

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator:Separate & get qualified abrasive

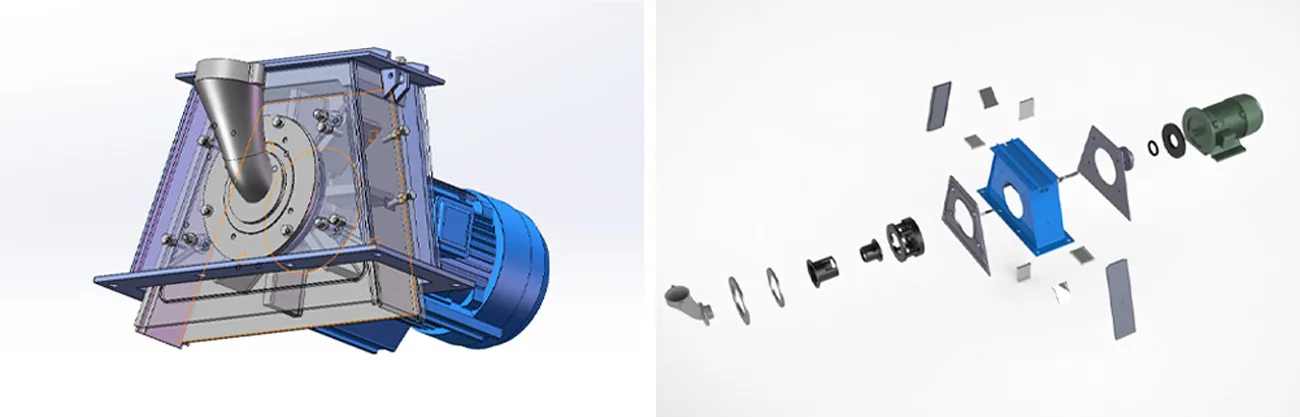

Blasting Turbine

Low scattering rate: The design controls the scattering rate below 5% to reduce equipment loss.

Modular design: Some models support quick disassembly and assembly, reducing maintenance costs.

Durability: The shell adopts wear-resistant protective plate welding technology, which does not require welding or replacement

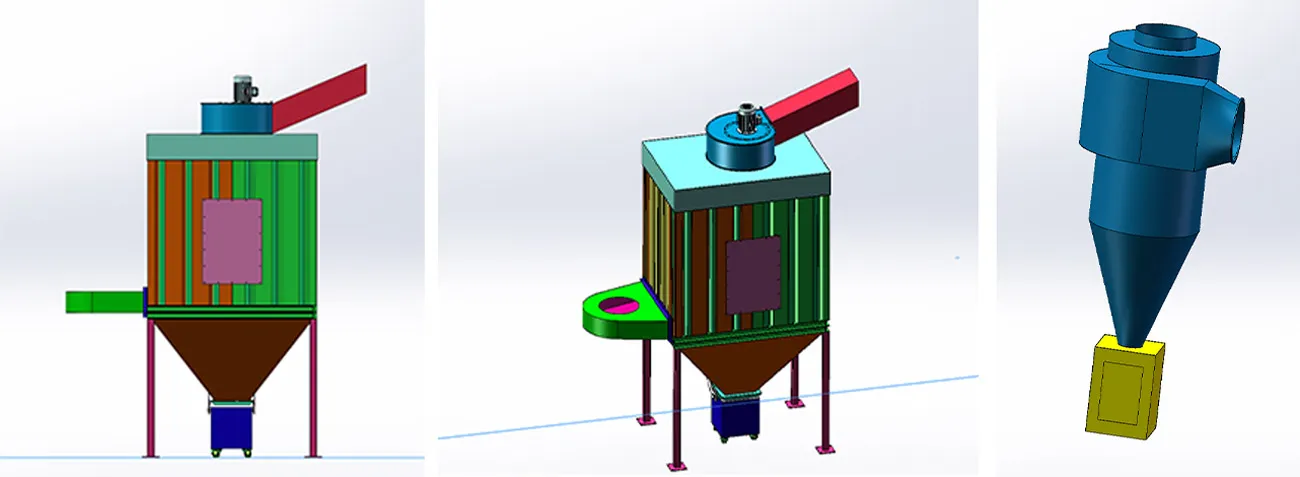

Dust Collection System

Filtration Rate: 99.9%, dustless

Cyclone Dust Collector: first sate dust collection.

Dust Collector: Cartridge or bag type

Fan Extractor:Extract dusts from piping to dust collector.

Ventilation Piping:Collect dusts from shot blasting chambers &separators.

High dust removal effect low pollution

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 50 g/m3. The fan power is 30 kw, ventilation quantity is 26000 m3/h.

Electric Control System

Model:Automatic or manual type

Control Unit: PLC .

P L C: Siemens, Omron or famous reliable brand in China for your choice.

Emergency Stop: on main control panel and rollers conveyors.

Power Indicator: available on control panel .

The roller conveyor shot blasting machine is an efficient continuous cleaning equipment for steel surface treatment. It is mainly suitable for surface rust removal, descaling and surface strengthening treatment of large workpieces such as steel plates, steel sections, H-shaped steels, steel structures, and pipes. The equipment transports the workpiece through the roller system, and uses multiple high-efficiency shot blasting machines in a closed shot blasting chamber to perform high-speed projectile impact treatment on the workpiece surface to achieve the purpose of pretreatment or final cleaning.

◆ Product Advantages

1. Wide application, Easy to install and use.

3. Good stability, Low failure rate (technical maturity, technical precipitation, skilled workers

2. Customized, Meet your needs.

4. Exquisite appearance (mature craft).

7. Factory direct selling with competitive price.

5. Large factories, Prompt delivery.

6. Strict quality inspection department.

10. Mainly electrical control system adoptsinternational brand.

8. Over 20 years' production experience.

9. Professional design team to serve you.

◆ Application Industry

◆ FAQ

What workpieces are suitable for through-type shot blasting machines?

Through-type shot blasting machines are suitable for continuous surface cleaning and rust removal of large quantities of steel plates, steel sections, welded structural parts, castings and forgings, and are widely used in industries such as ships, steel structures, and machinery manufacturing to improve the surface quality before painting.

What is the working principle of a through-type shot blasting machine?

The equipment delivers the workpiece into the shot blasting chamber through a conveyor roller or mesh belt. Multiple shot blasters throw projectiles at high speed to impact the surface of the workpiece, remove rust, oxide scale or sand, and achieve surface strengthening, thereby improving the durability and adhesion of the workpiece.

How to control dust and noise during the through-type shot blasting process?

The through-type shot blasting machine is equipped with an efficient dust removal system to effectively absorb the dust generated during the cleaning process to ensure that the workshop meets environmental protection standards; at the same time, it uses sound insulation panels and sealing structures to reduce noise pollution and improve the working environment.

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize,w_100/quality,q_100)