Hook Type Blast Cleaning Machine

Applicable to small and medium-sized complex castings, such as valves, pump bodies, motor housings, etc.

◆ Product Configuration

| Model | Q37 Ultra | Q37 Max | Q37 Pro |

| Motor | Siemens | WEG | ZWT |

| Electronic control | Siemens | Mitsubishi | Chint |

| Plc | ✔ | ✔ | ✘ |

| Shot blasting chamber | Mn13 12mm | Mn13 12mm | High chromium cast iron 10mm |

| Blasting turbine accessories | Precision casting | Precision casting | High chromium cast iron |

| Warranty time | 3 Years | 2 Years |

1 Years |

| remark |

All equipment can be equipped with automatic gates and double hooks |

◆ Product Parameters

| Type | Units | Q37 series(customizable) |

| Single hook hoisting | kg | 1000-8000 |

| Shot blasting capacity | kg/min | 2*200---4*250 |

| Splitter max separation volume | T/h | 25-60 |

| Bucket elevator lifting capacity | T/h | 25-60 |

| Clean workpiece size | mm | φ600-2000*Height1100-3000 |

| Total power | kw | 22-81 |

◆ Product Composition

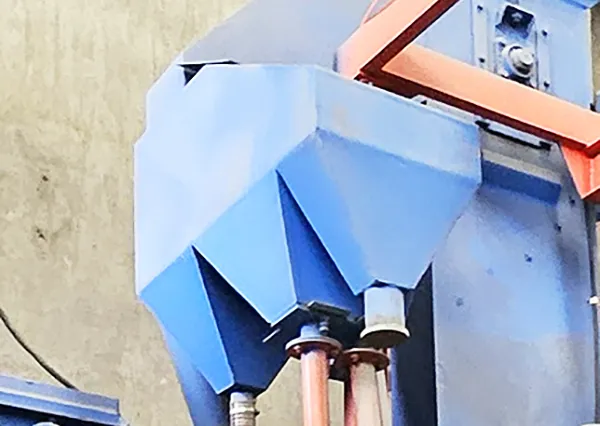

Spinner Hanger Hook System

Spinner Hanger Hook: To hang work pieces or tooling

Driving Motor: To drive spinner hanger hooks to rotate&move along rails into or out.

Overhead Rails: T shaped is for one hook and Y shaped is for two hooks

Rotating & Blasting Time: 3-5 minutes according to different work pieces

Blasting Chamber

Blasting Wheels: Mounted on left side wall of blasting chamber. Angle will be customized according to work pieces.

Hot Area: Right inside of blasting chamber is called hot area protected by Mn alloy liners.

Doors: Manual or pneumatic type are available.

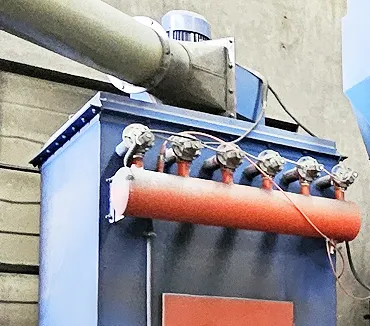

Abrasive Recycling System

Screw Conveyor: Mounted at basting chamber bottom to collect used steel shots and deliver to bucket elevator.

Bucket Elevator: To lift up used sheet shots to separator.

Separator:To separator qualified steel shots and grits by screen filtering and ventilation filtering.

Dust Collection System

Fan: Suck dust from blasting chamber through pipes.

Gravity Dust Collector: Catch big particle size dust by gravity as first sate dust collection.

Dust Collection: Bag type & cartridge type according to different filters. Efficiency: 99.9%

Electric Control System

Model: Automatic ( manual type is available).

Control Unit: PLC.

Emergency Stop: on main control panel and rollers conveyors.

Power Indicator: available on control panel.

The hook-type shot blasting machine is a highly versatile and widely used high-efficiency shot blasting cleaning equipment. It is mainly used for surface rust removal, descaling and strengthening treatment of medium and large castings, forgings, welded parts, steel structures and other workpieces. The equipment is suitable for cleaning workpieces with complex shapes, not suitable for rolling or need to avoid collision. It is widely used in casting, metallurgy, machinery, automobiles, engineering machinery, shipbuilding, steel structure and other industries.

◆ Product Advantages

Compact structure and small footprint: The equipment is reasonably designed and compactly laid out, suitable for users with limited plant space;

Convenient operation and maintenance: The human-machine interface is intuitive, the failure rate is low, daily maintenance is simple, and accessories are easy to replace;

Save labor and improve efficiency: Automatic operation reduces manual work, which is particularly suitable for batch and standardized production;

Strong customization: Non-standard customized solutions such as hook load, shot blasting capacity, and chamber size can be provided according to user needs;

Stable cleaning quality: With precise shot blasting angle and hook rotation control, the surface treatment of each workpiece is ensured to be uniform.

◆ Application Industry

◆ FAQ

What types of workpieces are suitable for the hook shot blasting machine?

The hook shot blasting machine is suitable for various medium and large castings, welded parts, forgings and workpieces with complex, irregular shapes and not suitable for rolling. It is especially suitable for parts that are afraid of collision or need to be suspended for cleaning, such as engine housings, steel structures, etc.

What is the working process of the hook shot blasting machine?

The workpiece is hoisted into the shot blasting room by the hook. After the equipment is started, it automatically rises and falls, rotates and performs multi-angle shot blasting cleaning. After the cleaning is completed, the hook withdraws and the workpiece is unloaded, realizing fully automatic or semi-automatic cycle operation.

How is the cleaning effect of the hook shot blasting machine?

The equipment adopts a reasonable arrangement of multiple high-efficiency shot blasting machines, combined with the automatic rotation function of the hook, which can achieve all-round and dead-angle cleaning, and the surface roughness can reach Sa2.5 level, meeting the subsequent process requirements such as spraying and electroplating.