Steel Plate Pretreatment

Applicable to various types of steel structural parts for buildings and engineering such as steel beams, steel columns, steel trusses, etc.

◆ Product Configuration

| Model | Q69 Ultra | Q69 Max | Q69 Pro |

| Motor | Siemens | WEG | ZWT |

| Electronic control | Siemens | Mitsubishi | Chint |

| Plc | ✔ | ✔ | ✘ |

| Shot blasting chamber | Mn13 16mm | Mn13 12mm | High chromium cast iron 10mm |

| Blasting turbine accessories | Mold steel | Precision casting | High chromium cast iron |

| Warranty time | 3 Years | 2 Years | 1 Years |

◆ Product Parameters

| Type | Q69(customizable) |

| The effective cleaning width(mm) | 800-4000 |

| The room feed-in size(mm) | 1000*400---4200*400 |

| The length of cleaning workpiece(mm) | 1200-12000 |

| The speed of conveyer(m/min) | 0.5-4 |

| The thicksness of cleaning steel sheet(mm) | 3-100 |

| The section steel specification(mm) | 800*300---4000*300 |

| The quantity of shot blasting(kg/min) | 4*180---8*360 |

| The first enclosed quantity(kg) | 4000---11000 |

| Roll brush adjusting height(mm) | 200---900 |

| Airness capacity(m3/h) | 22000---38000 |

| Exterior size(mm) | 25014*4500*9015 |

| Total power(except for dust cleaning)(kw) | 90---293.6 |

◆ Product Composition

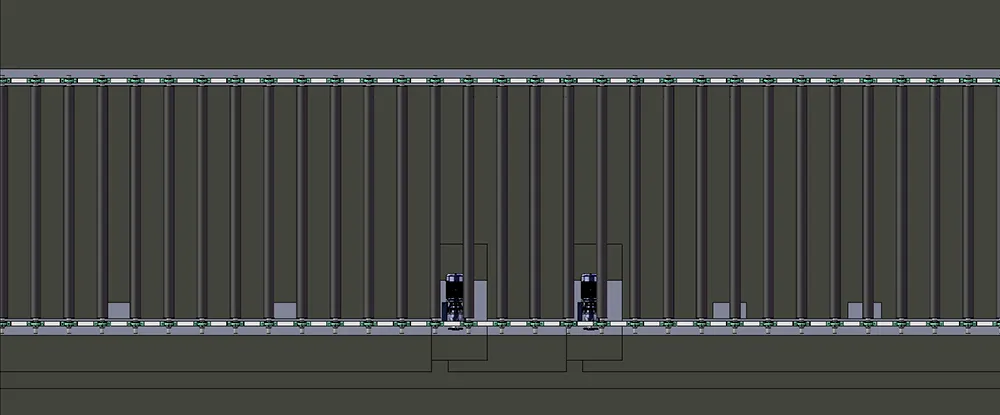

Roller Conveyor Systems

Composition: Feeding rollers, middle rollers, out-feeding rollers.

Loading capacity: 1000kgs/m

Rollers Distance: 450mm

Rollers Speed: 0.5-4 m per min.

Drive: Variable speed reducer.

Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

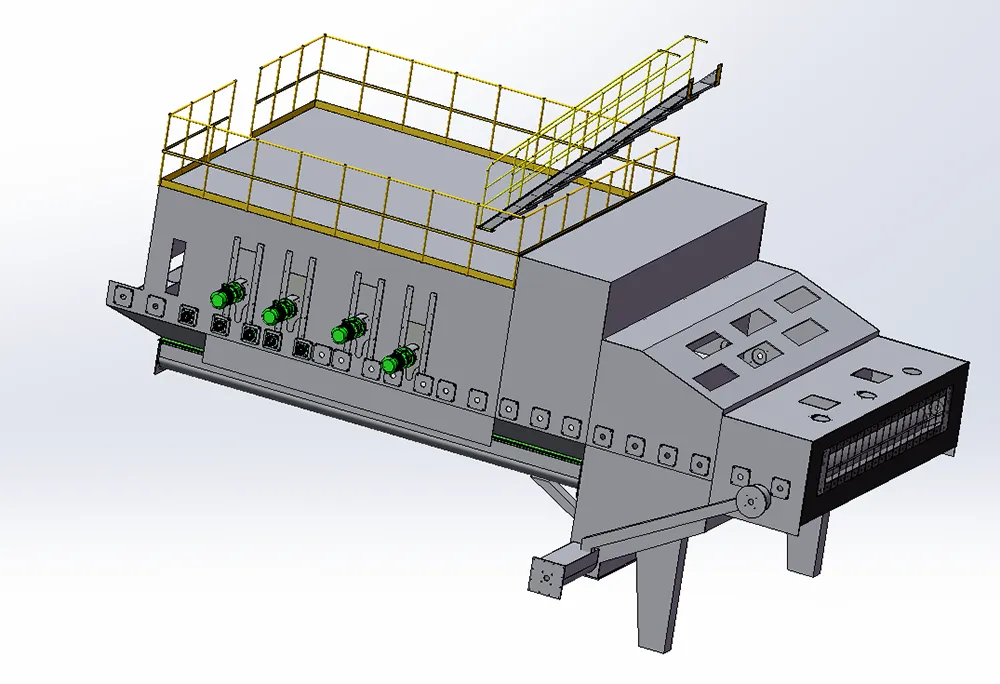

Blasting Chamber

Composition: Main blasting chamber, 2 auxiliary blasting chambers.

Auxiliary Blasting Chamber:Four layers rubber curtains

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles

Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit

replacement.

Abrasive Recycling System

Longitude Screw: collect abrasive at the bottom.

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator:Separate & get qualified abrasive

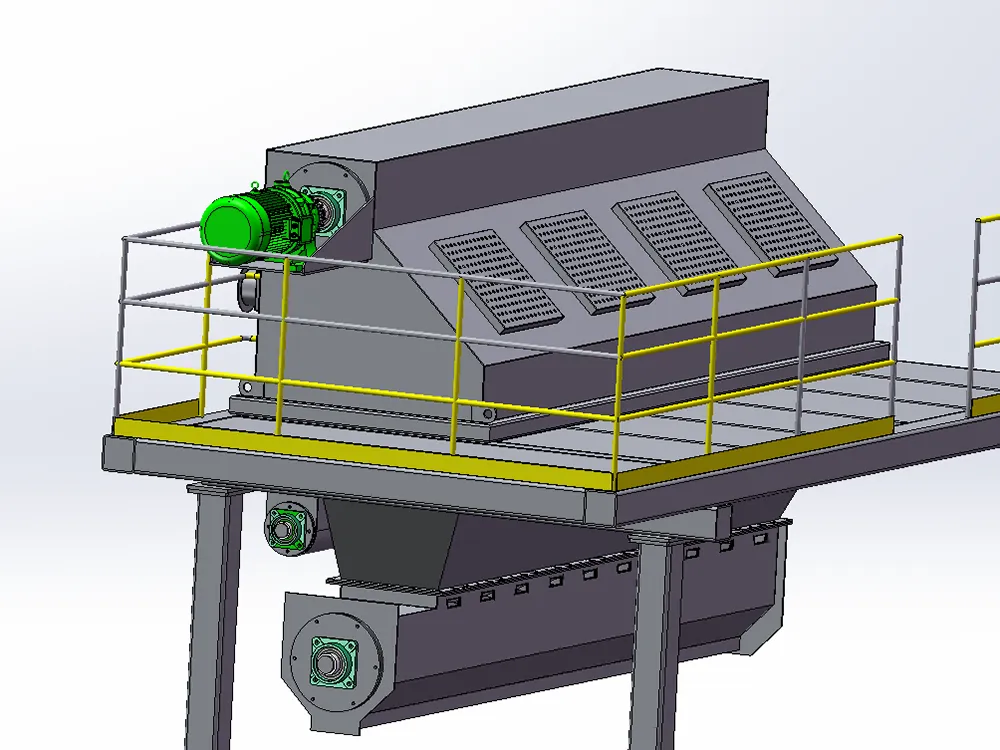

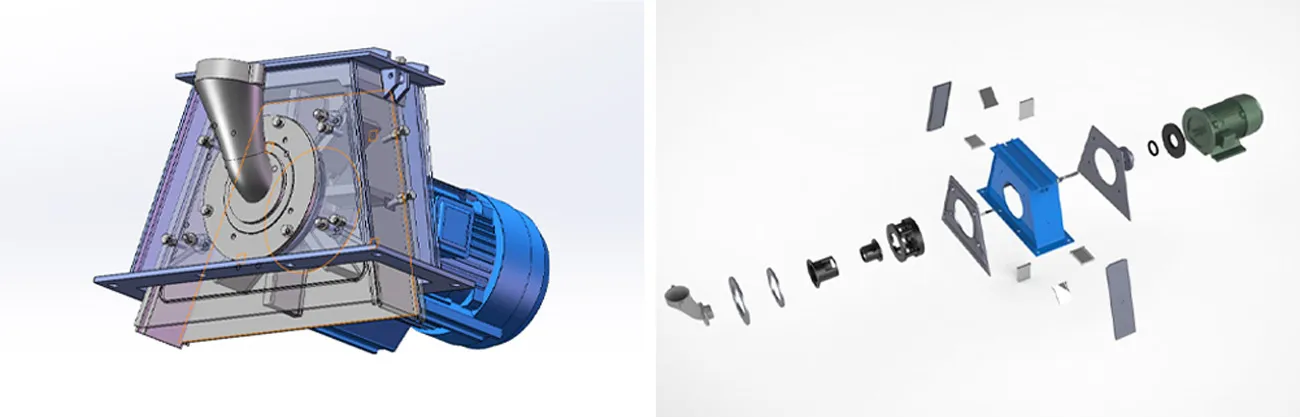

Blasting Turbine

1. The shell of the blasting turbine is made of 10 mm high-quality carbon steel plate by laser cutting and precise bending welding. The shell is positioned and welded with special tools to ensure the parallelism of the two ends of the shell and the concentricity of the holes.

2. The motor of shot blasting machine adopts excellent and controllable manufacturing process, with good sealing, dynamic balance, stable and reliable performance.

Advantages

1.Name: Wearable liner

Thickness: 10-12mm

Steel plate protection is used in cleaning room. Compared with the former rubber plate protection, its service life is greatly improved, and its appearance is beautiful and easy to replace.

2.The front and rear sealing chambers are suspended with 6 layers of rubber curtain (service life is more than 5000 hours), and the bottom of each chamber body is equipped with high elastic nylon brush row.

3.The suspension structure is convenient for removal and maintenance. The bottom brush row makes the seal tighter and prevents projectile flying out and dust escaping.

4. The entrance of the shot blasting chamber is equipped with a pulse wheel counting device and a workpiece width measuring device.

Electric Control

The Steel Plate Pretreatment Line is a fully automated production line that integrates multiple processes such as steel plate rust removal, spraying, and anti-corrosion. It is mainly used for surface cleaning and pre-coating treatment of metal materials such as steel plates and steel sections. The equipment continuously integrates processes such as shot blasting and spraying and drying. It has the characteristics of high efficiency, energy saving, high degree of automation, and environmental protection. It is an ideal surface treatment equipment for modern steel deep processing enterprises, shipbuilding, bridge construction, steel structure engineering and other industries.

The core purpose of the steel plate pretreatment production line is to remove rust, scale, oil and other impurities on the surface of the steel plate, improve the surface cleanliness of the steel and the adhesion of the coating, thereby extending the service life of the steel and improving its corrosion resistance.

◆ Application Industry

◆ FAQ

What are the applicable scopes of steel pipe shot blasting machines?

Steel pipe shot blasting machines are specially used to clean the rust, scale and welding slag on the inner and outer surfaces of various specifications of circular steel pipes, oil and gas pipelines, water pipes and other workpieces. They are suitable for pretreatment in petrochemical, shipbuilding, steel structure, construction and anti-corrosion pipeline industries.

What is the working principle of steel pipe shot blasting machines?

The steel pipe enters the shot blasting room through the conveyor roller, and the shot blaster evenly projects the steel shot onto the surface of the pipe body at high speed. The steel pipe is cleaned at multiple angles during rotation and advancement. After completion, the surface is clean and the roughness is consistent, which is convenient for subsequent spraying and anti-corrosion treatment.

What are the advantages of steel pipe shot blasting machines?

The steel pipe shot blasting machine can realize continuous automatic operation with high efficiency and is suitable for large-scale processing. The cleaning quality is stable and the environmental protection performance is good. It is equipped with an efficient dust removal system and abrasive recovery device to reduce dust pollution and waste of consumables and reduce operating costs.

.webp?x-oss-process=image/resize,w_100/quality,q_100)