Suspended Conveyor Shot Blasting Machine

Applied to castings such as engine cylinder blocks and cylinder heads

| Model | Single hook lifting weight | Clean workpiece size | Production efficiency (Hooks/hour) | Type |

| Q382 | 200 | φ500x1200 | 30-60 | Continuous type |

| Q383C | 250 | φ700x1200 | 30-60 | |

| Q384C | 400 | φ700x1500 | 40-70 | |

| Q483 | 300 | φ1060x1200 | 10-25 | Stepping type |

| Q485 | 500 | φ1200x1500 | 10-25 | |

| Q488 | 800 | φ1400x1800 | 10-25 | |

| Q583 | 300 | φ1000x1500 | 30-60 | Stacking type |

| Q585 | 500 | φ1200x1500 | 30-60 | |

| Q588 | 800 | φ1300x2400 | 30-60 |

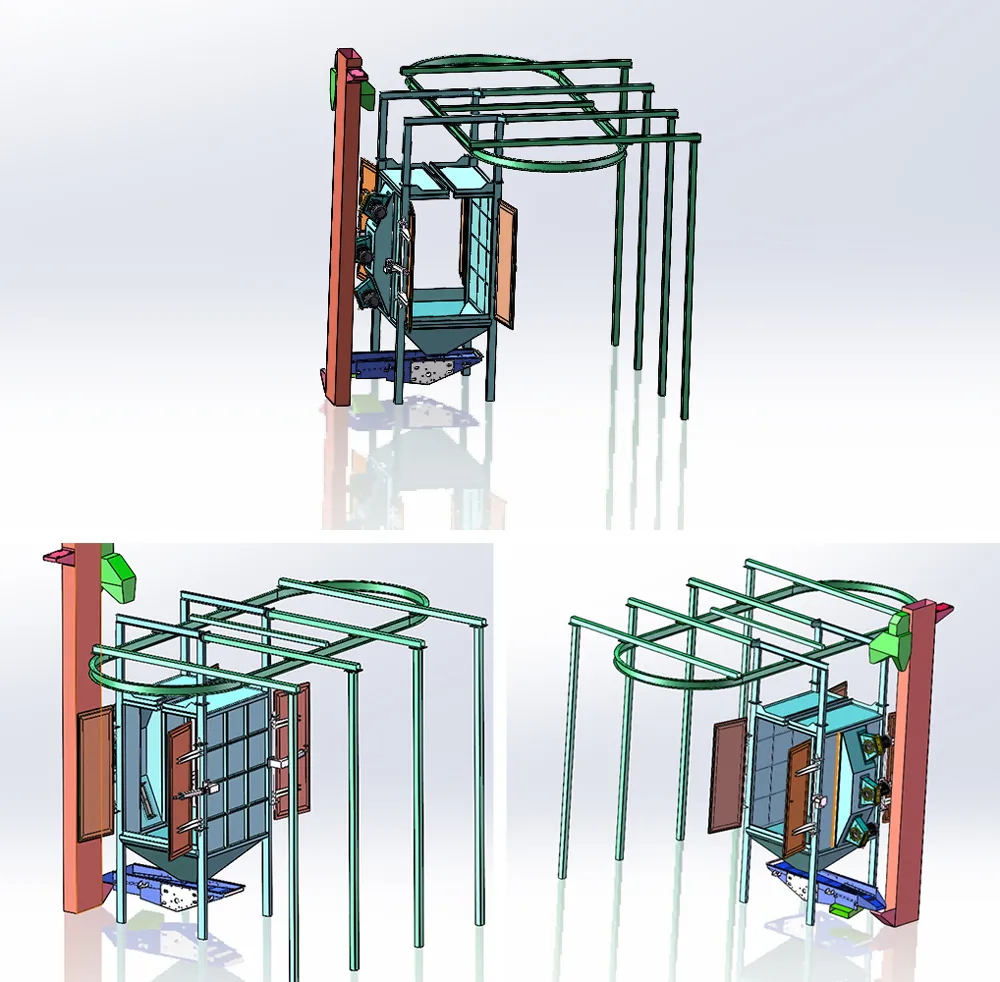

Cleaning room (shot blasting)——Customer provided or manufacturer provided conveyor suspension system

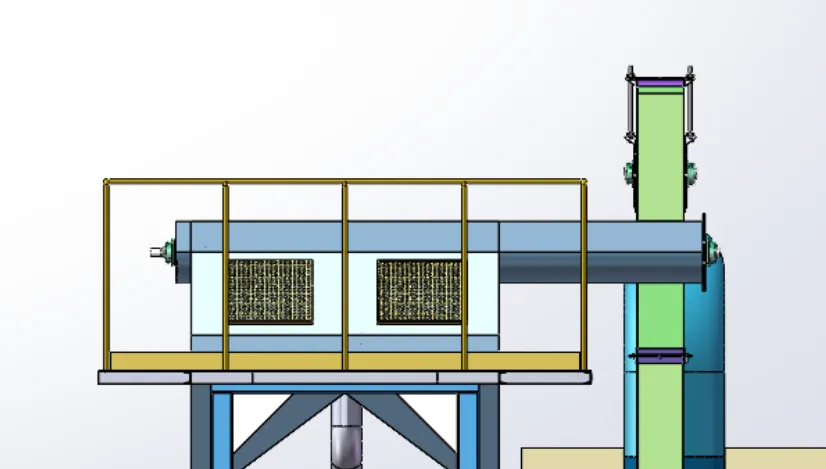

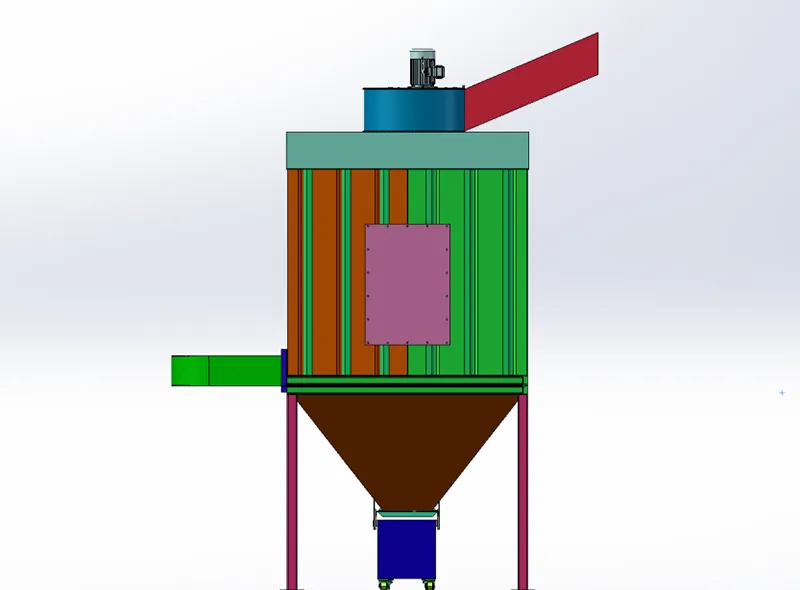

This cleaning room consists of a main and auxiliary cleaning rooms, which are large capacity chamber structures. The upper part of the room is box shaped and the lower part is conical. The steel plate thickness of the main room body is 10mm, and the steel plate thickness of the auxiliary room body is 6mm. Reinforcement ribs are made to enhance the strength of the room body.

The cleaning operation is carried out in a sealed chamber, which consists of front and rear auxiliary chambers, main chamber, rubber curtain, shot blasting chamber protective plate, blasting turbine, etc.

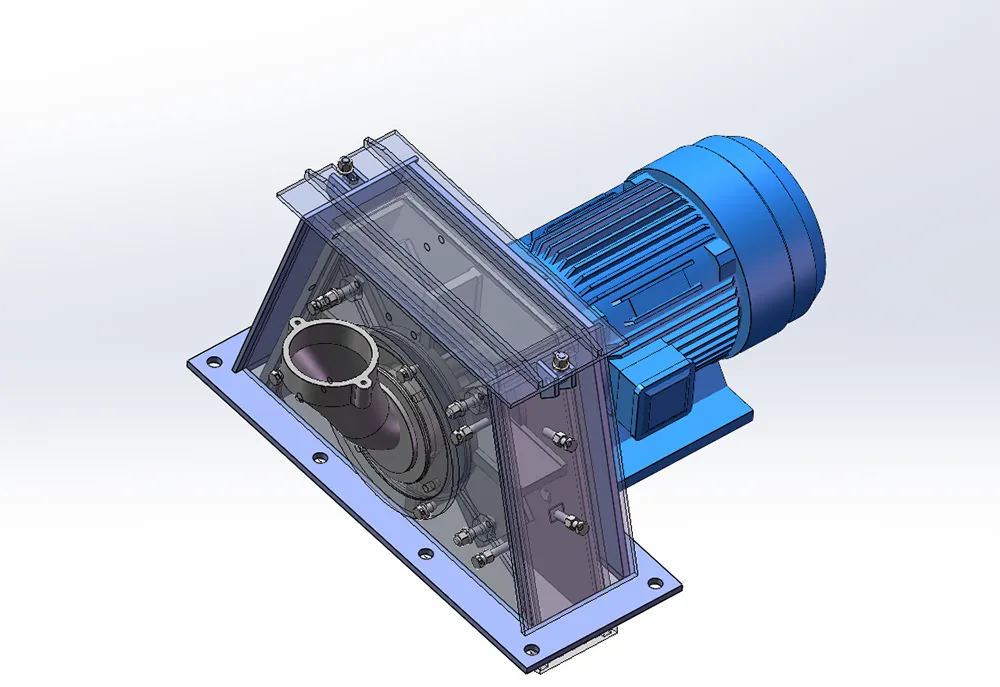

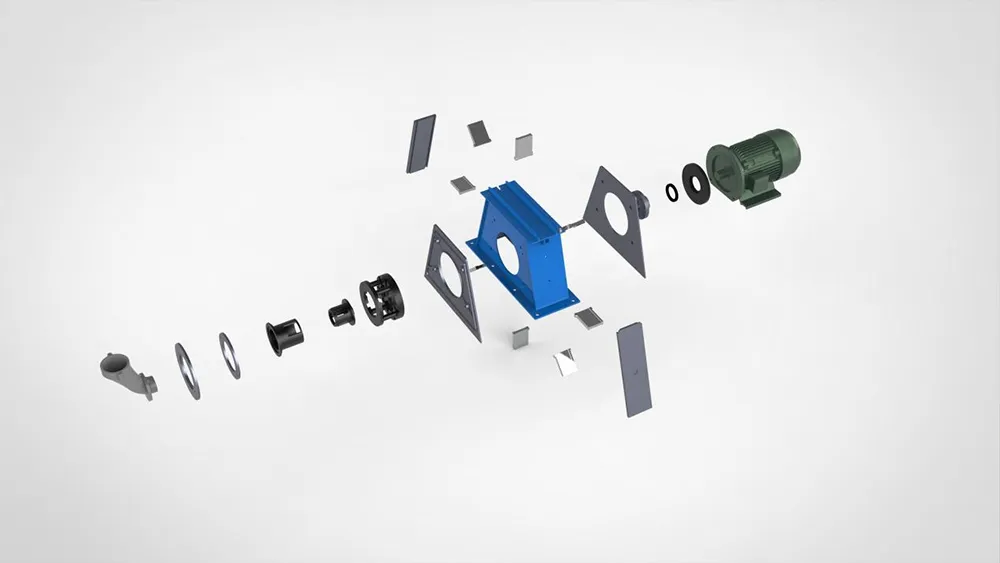

Blasting turbine

The blasting turbine manufactured by our company is produced by introducing advanced foreign technology. Composed of top guard plate, side guard plate, end guard plate, impeller, blade, directional sleeve, inlet pipe, etc. The projectile flows into the pellet sorting wheel through the inlet tube, undergoes pre acceleration, and is ejected through the directional sleeve. The blades continue to accelerate it and then rapidly eject it to achieve a strong impact on the workpiece, in order to achieve the purpose of cleaning.

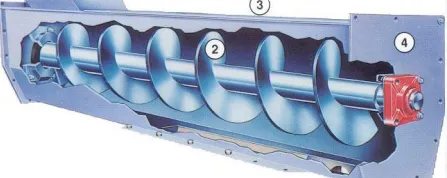

Spiral conveyor

The lower part of the cleaning room is equipped with a spiral conveyor and a chute, which can collect the powder dust mixture, collect it and send it to the elevator. After the elevator sends it to the separator, they are composed of a cycloidal pinwheel reducer, a spiral shaft, a housing, and a seat bearing.

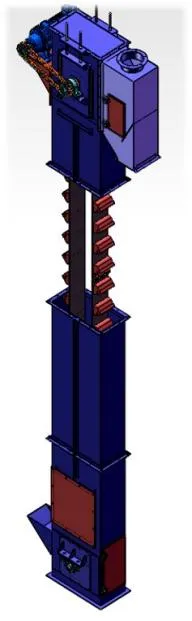

Bucket elevator

The bucket elevator consists of a cycloidal pinwheel reducer, upper and lower rollers, a conveyor chain, a hopper, a closed casing, and a tensioning device.

The feed inlet of the bucket elevator is connected to the vibrating conveyor screening machine, and its discharge outlet is connected to the magnetic separator. The lifting hood adopts a bent and welded structure. The lower cover of the hoist is equipped with a maintenance door, which can repair and replace the hoist hopper. Open the door cover on the lower casing to repair the lower transmission and troubleshoot. This machine uses a conveyor chain to rotate. When working, the hopper fixed on the conveyor chain lifts the pellets at the bottom of the elevator, and then under the driving force of the elevator, the pellets are sent to the top of the elevator. Finally, the pellets are dropped by centrifugal gravity and input into the pellet sand separator.

Separator

The separator adopts a BE type curtain structure with three-stage separation functions (pure pellets, mixture and sand mixture).

Dust collector

The ZCL series pulse blowback filter cartridge dust collector is a new generation of high-efficiency dust collector developed independently by our company by absorbing advanced dust collector technologies from both domestic and foreign sources. This dust collector has the characteristics of small volume, low operating resistance, and good dust removal effect.

The dust collector filter cartridge is manufactured according to a unified standard, using a new type of fabric and adopting a quick connection method, making it very convenient to disassemble and assemble the filter cartridge.

Electronic control system

The electrical control system adopts a PLC programmable controller to control the entire machine, and uses high-quality electrical components produced domestically and internationally, which have the advantages of high reliability and easy maintenance. The main circuit is equipped with small circuit breakers and thermal relays to achieve short circuit, phase loss, and overload protection for each motor. And there are multiple emergency stop switches installed to facilitate emergency shutdown and prevent accidents from escalating. Safety protection switches are installed on the cleaning room and various maintenance doors. When any maintenance door is opened, the shot blasting machine cannot be started.

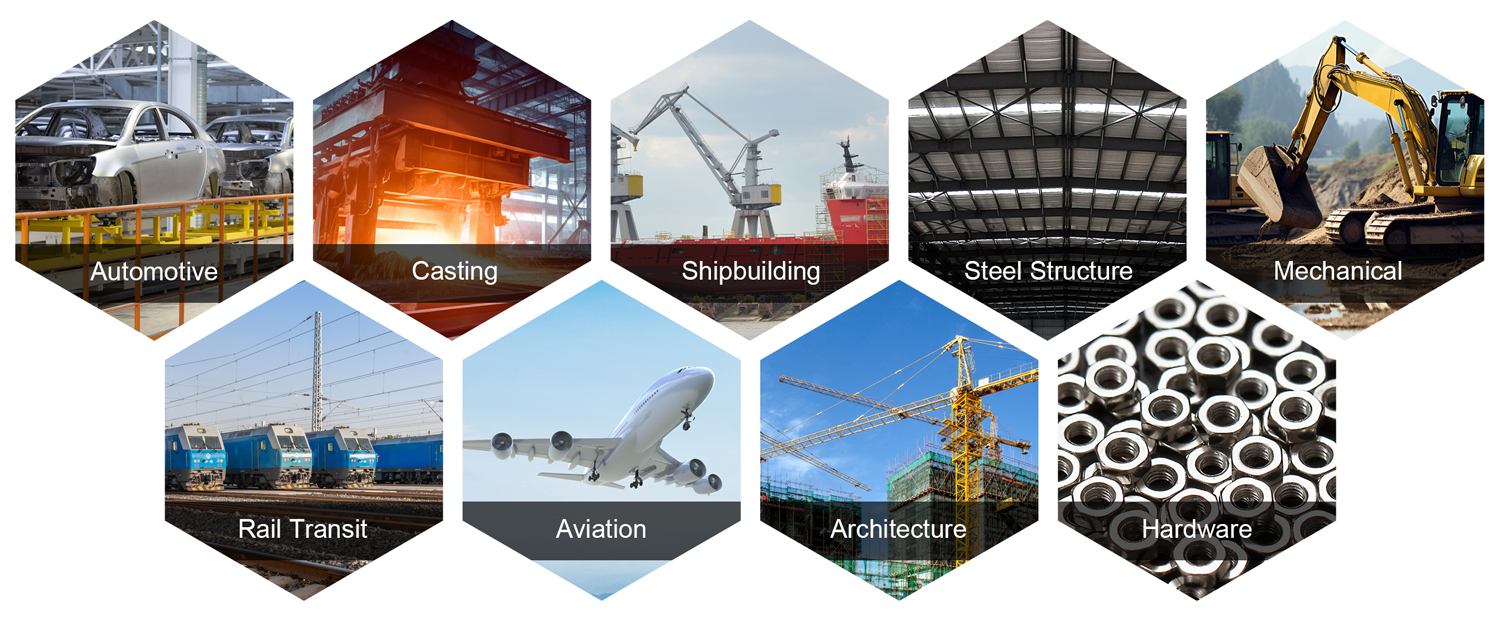

The catenary-through shot blasting machine is an efficient continuous shot blasting cleaning equipment suitable for the surface treatment of medium and large workpieces. It is widely used in automobile manufacturing, engineering machinery, casting, steel structure, machine tools, power equipment, boilers, valves and other industries. It is mainly used for rust removal, descaling and surface strengthening of complex structure workpieces such as castings, welded parts, forgings, heat-treated parts, etc. It is one of the indispensable important equipment in modern industry.

◆ Product Features

Adapt to complex workpiece structure

The workpiece is transported by hanging, not limited by shape, and is suitable for parts with complex structures such as holes, grooves, reinforcements, and curved surfaces.

Flexible switching of multiple operating modes

It can realize continuous through-type, step-by-step, swing positioning and other operating modes to meet different production and processing requirements.

Multi-angle shot blasting without dead angles

The shot blasting machine is reasonably laid out, and the projectiles can cover the entire surface of the workpiece from multiple directions to ensure uniform and thorough cleaning effect.

High degree of automation

The whole process of workpiece loading and unloading, conveying, shot blasting, and unloading is automatically controlled, which is easy to operate and reduces manual intervention.

High wear-resistant structure design

The shot blasting room adopts high chromium alloy wear-resistant lining, which is impact-resistant and wear-resistant, effectively extending the service life of the equipment and reducing maintenance costs.

Excellent environmental performance

Equipped with an efficient pulse dust removal system, the dust collection rate is high, ensuring no pollution emissions during the cleaning process, meeting environmental protection requirements.

◆ Product Advantages

High production efficiency: The catenary conveying method can realize the simultaneous cleaning of multiple workpieces, greatly improving production capacity;

Strong flexibility and wide adaptability: Suitable for continuous production of multiple varieties, small batches or large batches, with strong application flexibility;

Good safety: The equipment is equipped with multiple safety interlocking devices to ensure the safety of personnel and equipment during operation;

Convenient maintenance: Modular design facilitates equipment maintenance and replacement of wearing parts, reducing the cost of use;

Strong customizability: Tailor-made solutions can be provided according to the customer's workpiece size, weight and cleaning process requirements.

◆ Application Industry

◆ FAQ

What workpieces are suitable for through-type shot blasting machines?

Through-type shot blasting machines are suitable for continuous surface cleaning and rust removal of large quantities of steel plates, steel sections, welded structural parts, castings and forgings, and are widely used in industries such as ships, steel structures, and machinery manufacturing to improve the surface quality before painting.

What is the working principle of a through-type shot blasting machine?

The equipment delivers the workpiece into the shot blasting chamber through a conveyor roller or mesh belt. Multiple shot blasters throw projectiles at high speed to impact the surface of the workpiece, remove rust, oxide scale or sand, and achieve surface strengthening, thereby improving the durability and adhesion of the workpiece.

How to control dust and noise during the through-type shot blasting process?

The through-type shot blasting machine is equipped with an efficient dust removal system to effectively absorb the dust generated during the cleaning process to ensure that the workshop meets environmental protection standards; at the same time, it uses sound insulation panels and sealing structures to reduce noise pollution and improve the working environment.

◆ Company Introduction

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is the leading enterprise of the shot blasting machine industrial cluster in Dafeng District and has the title of "China Xituan Shot Blasting Machine Industrial Base".

Founded in May 2003, the company is a professional manufacturer of shot blasting equipment and accessories integrating R&D, design, manufacturing and sales. The company is located in Longfa Industrial Park, Xituan Town, Dafeng District. The registered capital is RMB 60 million, with 180 employees, including 40 scientific and technological personnel. The company currently covers an area of about 120 acres and a current construction area of 80,000 square meters.

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is located on the beautiful coast of the Yellow Sea, close to the Ningjingyan Expressway, Xinchang Railway and Tongyu River Golden Waterway, and close to Yancheng Airport for convenient transportation and communication. It has built a new plant and a supporting service system for technical and process collaboration, and has a complete set of gold processing equipment and dynamic balancing instruments and other testing methods.

The company always adheres to the quality tenet of "honesty and dedication, serving customers with sincerity", and the quality commitment of "meticulous manufacturing, ensuring satisfaction of each casting machine", and is determined to repay the society with quality, constantly carry out technological innovation, establish the good reputation of the "Longfa" brand, and do its best for the development of my country's casting machinery industry. All colleagues in the company warmly welcome friends from all walks of life at home and abroad to come to guide, exchange and cooperate, and create brilliance together!

.webp?x-oss-process=image/resize,w_100/quality,q_100)