Mesh Belt Through-Type Shot Blasting Machine

Applied to large stamping parts such as automobile beams and body panels

◆ Product Configuration

| Model | Q Series |

| Mesh belt width(mm) | 600-1800 |

| Height | 500 |

| Cleaning speed(m/min) | 0.5-4 |

| Shot blasting volomn(kg/min) | 4*120-10*250 |

| Total power(Kw) | 60-215 |

◆ Product Configuration

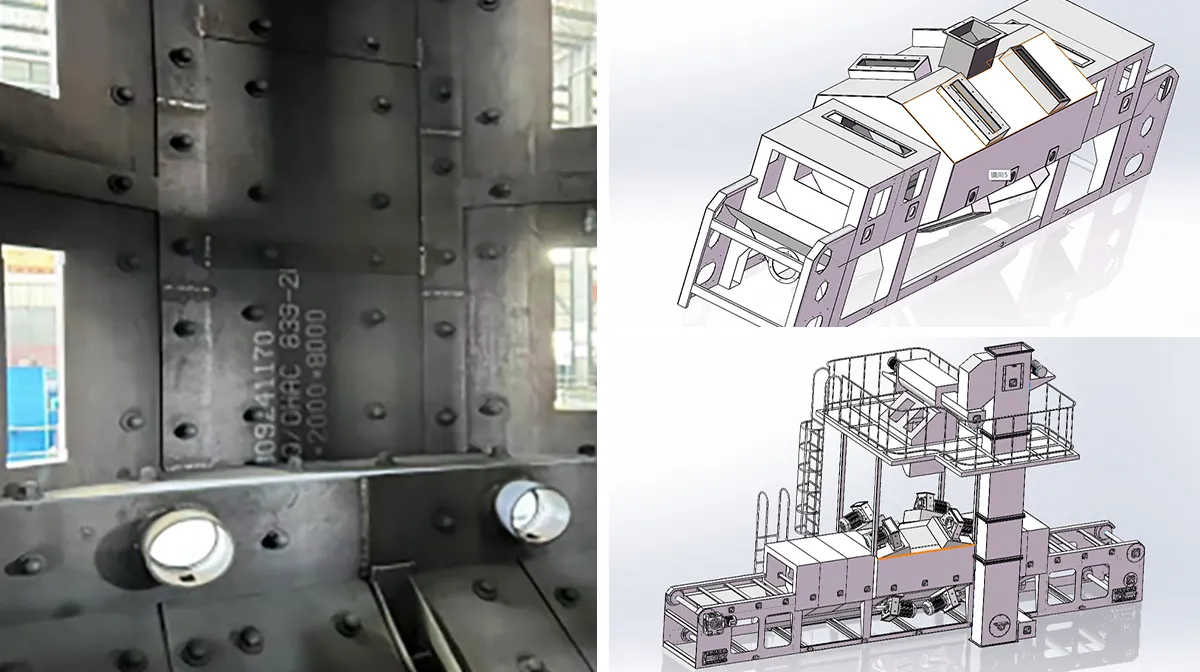

Shot blasting room

-The various components of the equipment are cut using laser cutting to improve the accuracy of the product

-The main chamber is entirely made of Mn13 high-strength manganese steel plate rolled by Taiyuan Iron and Steel Co., Ltd;

-Manganese steel plate with a thickness of 12mm and a service life of over 3 years;

-The manganese steel plate protective plate is welded and fixed as a whole, reducing maintenance costs in the later stage; Add another layer of manganese steel plate with a thickness of 24mm to cover the vulnerable areas.

-Add multiple rollers to the mesh belt of the shot blasting room; Manganese steel plate protective rings on both sides.

-The mesh belt of the shot blasting room is equipped with anti deviation limit at the inlet and outlet;

-The shot blasting room is equipped with dual ventilation to increase the flow of air inside the room and reduce dust spillage during cleaning.

Note: Mn13 steel plate is the best choice for wear-resistant materials that resist strong impacts. Under the action of large impact loads, the surface of the steel plate hardens, and the surface hardness can reach HB500 or above, thus producing a high wear-resistant surface. As the surface hardening layer wears away, a new hardening layer will continuously form.

Mesh belt conveyor

-Using Mn13 steel wire, with a service life of over 6000 hours;

-Mesh belt threading with a diameter of 8mm, integrated weaving technology, and argon arc welding process.

-Hidden dual drive for import and export, using seamless steel pipe wrapped with adhesive and thickened anti slip treatment.

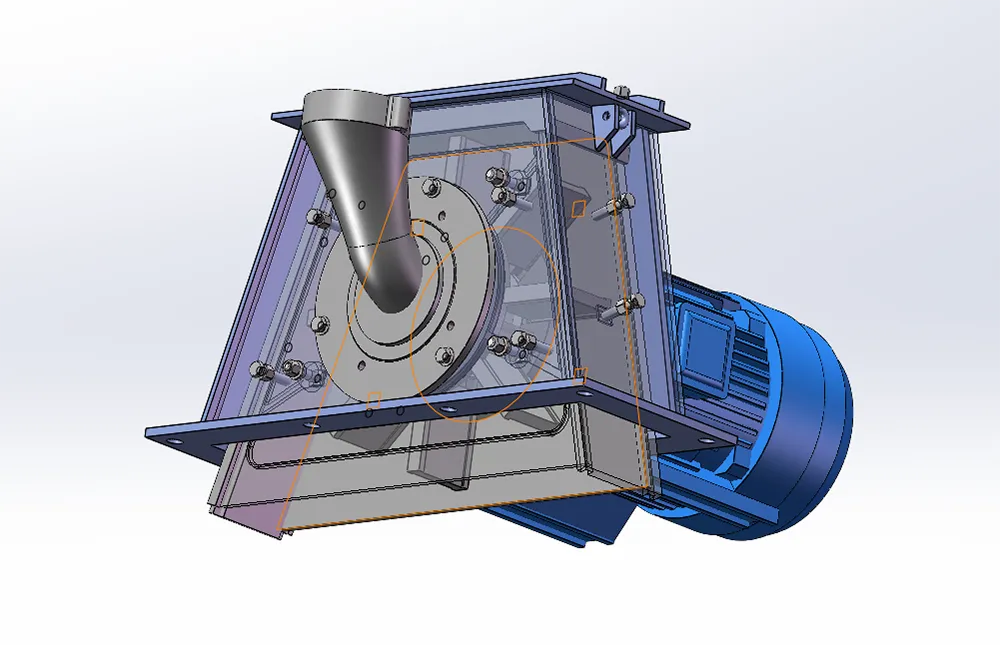

Blasting turbine

The shot blasting equipment manufactured by our company is produced with the introduction of Shinto Technology from Japan. Composed of blasting turbine guard plate, side guard plate, end guard plate, impeller, blade, directional sleeve, inlet pipe, etc. The abrasive flows into the pellet wheel through the inlet tube, and after pre acceleration, it is ejected through the directional sleeve. The blades continue to accelerate it and then rapidly eject it to achieve strong impact on the workpiece, in order to achieve the purpose of cleaning.

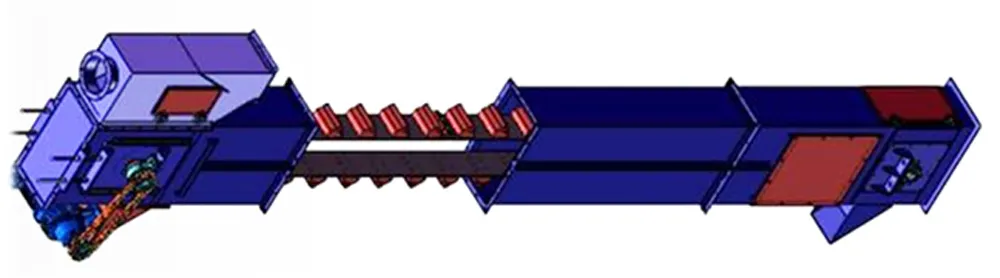

Bucket elevator

The bucket elevator consists of a cycloidal pinwheel reducer, upper and lower rollers, a conveyor chain, a hopper, a closed casing, and a tensioning device.

The feed inlet of the bucket elevator is connected to the screw conveyor, and its discharge outlet is connected to the separator.

The bucket elevator cover adopts a bent and welded structure. The lower cover of the hoist is equipped with a maintenance door, which can repair and replace the hoist hopper. Open the door cover on the lower casing to repair the lower transmission and troubleshoot. This machine uses a conveyor chain to rotate. When working, the hopper fixed on the conveyor chain lifts the pellets at the bottom of the elevator, and then under the driving force of the elevator, the pellets are sent to the top of the elevator. Finally, the pellets are dropped by centrifugal gravity and input into the pellet sand separator.

The lower shaft of the bucket elevator is equipped with a pulse wheel, which can detect the working status of the elevator. Once faults such as the lower shaft not rotating occur, the signal can be promptly fed back to the PLC for processing, and an alarm can be triggered through the alarm to ensure the safe operation of the equipment.

Separator

The separator adopts a BE type curtain structure with three-stage separation functions (pure pellets, mixture and sand mixture). The pellet dust mixture is uniformly fed into the separation zone by the feeding screw conveyor, forming a uniform pellet dust flow curtain, and passing through a horizontal airflow of 5-6m/s for pellet dust separation. The pellets and waste materials fall into their respective channels according to their specific gravity, resulting in pure pellets; After falling into the grid and sieving, it enters the hopper for use by the shot blasting machine. Fine dust is sucked into the dust removal system, and the purified gas is discharged into the atmosphere. The particulate dust is captured and collected.

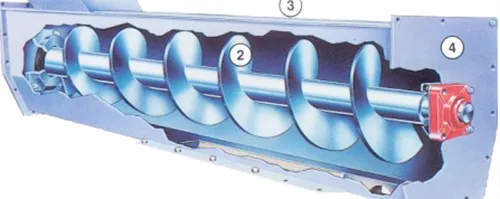

Vertical screw conveyor,Horizontal screw conveyor

The lower part of the cleaning chamber is equipped with a screw conveyor and a shot chute, which can collect the shot and dust mixture, summarize it and send it to the elevator. Then, it is sent to the separator by the elevator. They are composed of a cycloidal pinwheel reducer, a screw shaft, a shell, a mounted bearing, etc.

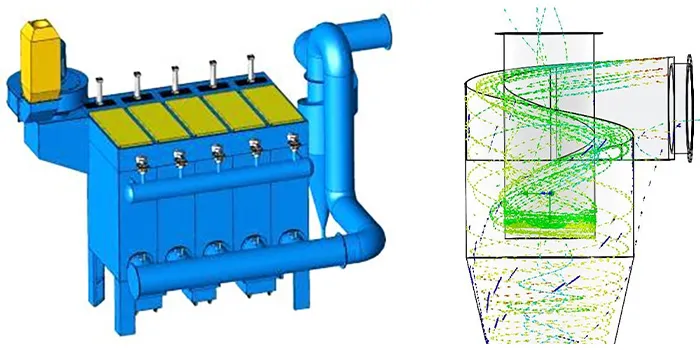

Dust collector

The dust removal system is composed of a bag mounting box, a fan, suction pipes, exhaust pipes, pulse valves, compartment-based lifting cylinders, dust collection boxes, etc. The compartmentalized pulse bag dust collector adopts an offline cleaning method. The compartments are isolated from each other. During cleaning, the processing compartments remain in a static state. After the pulse strikes the bags, there will be no secondary dust raising. The bags in the dust removal compartments are in a state of cyclic pulse impact, with high dust removal efficiency and a dust filtration efficiency of 99.9%. The pulse bag dust collector is convenient for installation and maintenance. The dust content in the air purified by the dust removal system is much lower than the national smoke and dust emission standards. The dust collector bags are made of imported microporous film composite fireproof filter material. On the one hand, it does not burn when exposed to open flames or sparks, and even if the dust contains sparks, it will not cause the filter bag to catch fire, while improving the filtration accuracy. On the other hand, it is conducive to removing the dust adhering to the filter bag, and the skeleton filter bag can be conveniently disassembled and replaced.

Electronic control system

The entire line adopts programmable PLC control for automatic operation, and the system is equipped with automatic program switch and manual control switch, which can be converted to each other.

The PLC adopts Mitsubishi from Japan, and the electrical components use Chint brand. The entire line is automatically tested, with national standard three color warning, safety interlock, and fault alarm.

Usually, there is an indicator light on the panel to check if it is working properly, so that it can be detected at any time

The mesh belt through-type shot blasting machine is a continuous and efficient surface cleaning equipment, which is mainly suitable for batch continuous shot blasting of small and medium-sized workpieces. The equipment smoothly transports the workpiece to the shot blasting cleaning room through the mesh belt conveyor system, and uses the high-speed rotating shot blaster to project the projectiles at high speed onto the workpiece surface to remove scale, rust, molding sand or other impurities, and improve the surface quality and fatigue resistance of the workpiece.

◆ Product Advantages

Continuous and efficient operation

The mesh belt conveyor structure realizes the continuous passage of the workpiece, greatly improves the production efficiency, is suitable for batch and assembly line operations, and is particularly suitable for beat production mode.

Multi-angle shot blasting coverage, no cleaning dead angle

The shot blaster adopts a multi-angle arrangement, so that the projectile can fully cover the workpiece surface from multiple directions to ensure thorough cleaning, especially for workpieces with complex shapes, holes or grooves.

The mesh belt conveyor is stable and widely applicable

The mesh belt is made of high-strength alloy steel, with good wear resistance and strong load-bearing capacity. It is suitable for various irregular shapes, small volumes but large numbers of workpieces. The conveying speed is adjustable to meet the requirements of different process beats.

Intelligent control system, easy operation

The PLC automatic control system can realize automatic start-up, operation monitoring, fault alarm, parameter adjustment and other functions, improving the convenience and safety of operation.

Excellent environmental performance

Equipped with advanced pulse back-blowing dust collector, the dust generated during the cleaning process is effectively collected and processed to meet environmental emission standards and improve the working environment.

Easy maintenance and low operating cost

Modular design, easy maintenance and replacement of wearing parts. The projectiles are recycled to reduce consumption costs, the whole machine has low energy consumption and strong economy.

◆ Application Industry

◆ FAQ

What workpieces are suitable for through-type shot blasting machines?

Through-type shot blasting machines are suitable for continuous surface cleaning and rust removal of large quantities of steel plates, steel sections, welded structural parts, castings and forgings, and are widely used in industries such as ships, steel structures, and machinery manufacturing to improve the surface quality before painting.

What is the working principle of a through-type shot blasting machine?

The equipment delivers the workpiece into the shot blasting chamber through a conveyor roller or mesh belt. Multiple shot blasters throw projectiles at high speed to impact the surface of the workpiece, remove rust, oxide scale or sand, and achieve surface strengthening, thereby improving the durability and adhesion of the workpiece.

How to control dust and noise during the through-type shot blasting process?

The through-type shot blasting machine is equipped with an efficient dust removal system to effectively absorb the dust generated during the cleaning process to ensure that the workshop meets environmental protection standards; at the same time, it uses sound insulation panels and sealing structures to reduce noise pollution and improve the working environment.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)