Turntable Shot Blasting Machine

Applied to small metal parts such as metal casings and radiators of electronic equipment

Turntable Shot Blasting Machine is a surface treatment equipment for fixed-point and directional efficient cleaning of small and medium-sized workpieces. It uses a high-speed rotating shot blaster to project metal projectiles at high speed onto the surface of the workpiece to remove scale, rust, welding slag and other impurities, while achieving surface strengthening. The equipment has a compact structure and precise cleaning. It is particularly suitable for single-piece or small-batch processing of workpieces with regular geometric shapes and not easy to roll. It is widely used in molds, flanges, disc parts, pump housings, valve bodies and other fields.

◆ Product Features

Compact structure and small footprint

The equipment is reasonably designed and suitable for installation on the side of the production line or on an independent workstation. It does not take up a lot of space and is suitable for small manufacturing companies.

High cleaning accuracy

The slow rotation of the workpiece on the turntable makes the shot blasting angle more stable, ensuring uniform surface treatment without dead angles and improving the cleaning quality.

A variety of turntable configurations are available

Single turntable, double turntable, lifting turntable, flip table and other configurations are provided to meet the cleaning needs of workpieces of different types and shapes.

Can be equipped with automatic loading and unloading system

Supports automatic loading and unloading methods such as automatic robotic arms and fixtures, reducing manual intervention and improving efficiency and safety.

Environmental dust removal system

Equipped with pulse back-blowing dust collector, high dust capture rate, emissions meet environmental standards, and effectively improve the working environment.

Convenient operation and high safety

Friendly human-machine interface, PLC control system with automatic start, alarm and emergency stop functions to ensure safe and reliable operation.

◆ Product Advantages

Excellent cleaning effect: especially suitable for workpieces with high surface quality requirements such as precision parts, molds, flanges, etc.;

Energy saving and consumption reduction: Shot recycling, reducing material waste, simple structure, easy maintenance;

Strong adaptability: suitable for surface treatment of workpieces of various materials (cast iron, aluminum alloy, steel, etc.);

Easy to maintain: key components adopt modular design, easy replacement, and reduce downtime;

Support customization: equipment parameters and structural forms can be tailored according to customer workpiece size, weight, and process requirements.

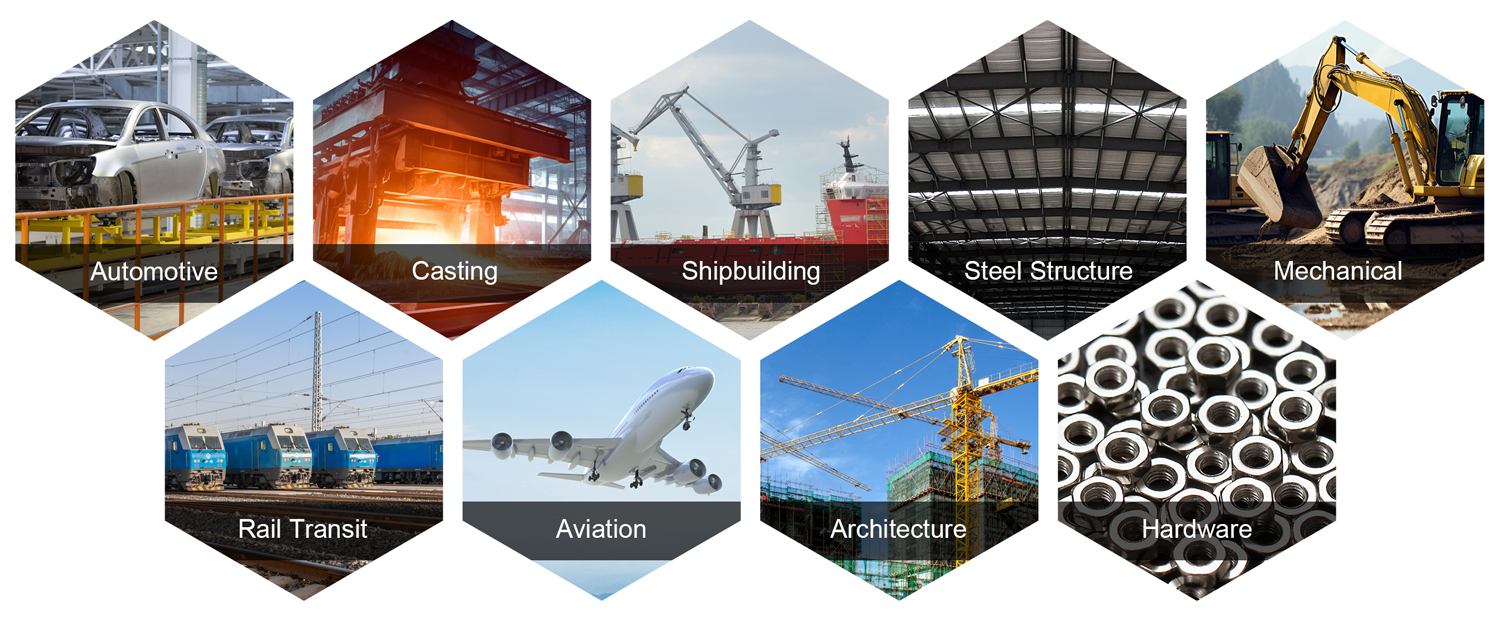

◆ Application Industry

◆ FAQ

What workpieces are suitable for cleaning with Turntable Shot Blasting Machine?

The turntable shot blasting machine is suitable for cleaning workpieces with regular shapes, medium sizes, and not easy to roll, such as molds, flanges, gear rings, pump housings, valve bodies, etc. Its turntable structure enables the workpiece to rotate automatically in a fixed position, ensuring uniform cleaning and no dead angles, which is particularly suitable for high-demand surface treatment processes.

How does Turntable Shot Blasting Machine ensure the cleaning effect?

The equipment uses the turntable to slowly rotate and multiple shot blasters to accurately project steel shots to achieve all-round and efficient cleaning of the workpiece. Parameters such as speed and shot blasting amount are adjustable to ensure uniform cleaning and meet the surface quality requirements of subsequent processes such as spraying and electroplating.

Does Turntable Shot Blasting Machine support automation?

Yes, the turntable shot blasting machine can be equipped with automatic loading and unloading devices, robotic arms, workpiece fixtures, etc., and supports automated operation. With the PLC control system, the entire process of cleaning, rotation, and unloading can be automated to improve production efficiency and reduce labor costs.

◆ Company Introduction

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is the leading enterprise of the shot blasting machine industrial cluster in Dafeng District and has the title of "China Xituan Shot Blasting Machine Industrial Base".

Founded in May 2003, the company is a professional manufacturer of shot blasting equipment and accessories integrating R&D, design, manufacturing and sales. The company is located in Longfa Industrial Park, Xituan Town, Dafeng District. The registered capital is RMB 60 million, with 180 employees, including 40 scientific and technological personnel. The company currently covers an area of about 120 acres and a current construction area of 80,000 square meters.

Jiangsu Longfa Casting Rust Removal Equipment Co., Ltd. is located on the beautiful coast of the Yellow Sea, close to the Ningjingyan Expressway, Xinchang Railway and Tongyu River Golden Waterway, and close to Yancheng Airport for convenient transportation and communication. It has built a new plant and a supporting service system for technical and process collaboration, and has a complete set of gold processing equipment and dynamic balancing instruments and other testing methods.

The company always adheres to the quality tenet of "honesty and dedication, serving customers with sincerity", and the quality commitment of "meticulous manufacturing, ensuring satisfaction of each casting machine", and is determined to repay the society with quality, constantly carry out technological innovation, establish the good reputation of the "Longfa" brand, and do its best for the development of my country's casting machinery industry. All colleagues in the company warmly welcome friends from all walks of life at home and abroad to come to guide, exchange and cooperate, and create brilliance together!

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)